How Expert Commercial Refrigerator Repair Can Increase Your Company Effectiveness

How Expert Commercial Refrigerator Repair Can Increase Your Company Effectiveness

Blog Article

Repairing Commercial Refrigeration Fixing: Strategies for Quick and Effective Fixes

In the realm of industrial refrigeration, the need for swift and precise troubleshooting approaches is extremely important. When a refrigeration device breakdowns, the repercussions can be costly and turbulent to organization procedures. Comprehending the common issues that plague business refrigeration systems and having a toolkit of analysis methods at your disposal can make all the distinction in swiftly identifying and remedying troubles. As we navigate with the ins and outs of fixing industrial refrigeration fixing, we will uncover the vital methods for settling issues successfully, guaranteeing that organizations can keep optimal air conditioning efficiency and reduce downtime.

Common Business Refrigeration Concerns

Business refrigeration systems generally encounter a range of functional issues that can disrupt their efficiency and efficiency. One common problem is incorrect temperature control, which can lead to food perishing and waste if not promptly addressed.

Additionally, cooling agent leaks pose a significant problem as they not just influence the air conditioning capability of the system but additionally add to environmental harm. Discovering and repairing leaks promptly is critical to stop additional damages and make sure compliance with guidelines. Additionally, dirty condenser coils can impede warmth transfer, forcing the system to function more challenging and take in even more energy. Normal cleaning and upkeep can assist stop this issue and lengthen the life expectancy of the refrigeration system.

Analysis Tools and Techniques

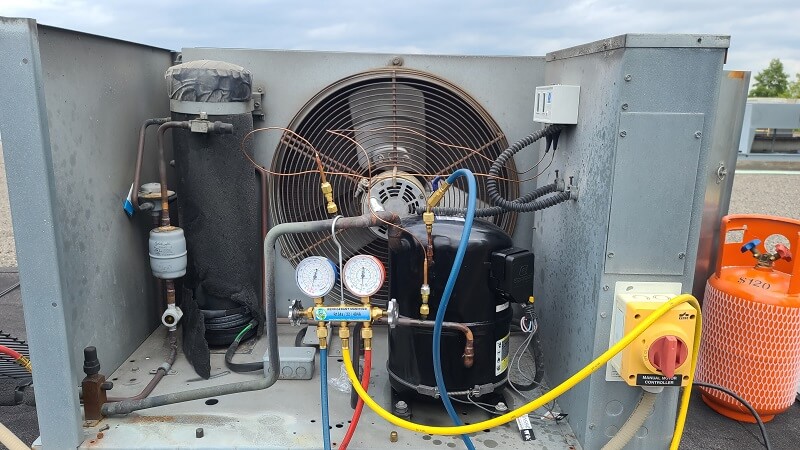

Reliable troubleshooting of business refrigeration systems counts heavily on utilizing specialized diagnostic devices and strategies to identify and deal with underlying concerns effectively - commercial refrigeration repair. In addition, leakage discovery tools like digital leak detectors or ultraviolet dye kits are crucial for finding refrigerant leaks that can lead to system inefficiencies.

Information loggers can be employed to keep track of system efficiency over time and identify patterns that might show recurring troubles. By combining these diagnostic tools and strategies, technicians can successfully repair commercial refrigeration systems and offer quick and specific repair work, reducing downtime and making certain optimum system performance.

Quick Repairs for Refrigeration Troubles

When encountered with refrigeration troubles, specialists can implement quick fixes to address typical concerns swiftly and successfully. One common fast solution is looking for a dirty condenser coil, which can trigger the system to run inefficiently. Cleansing the condenser coil frequently can boost the system's performance and stop overheating. An additional fast repair is making certain that the refrigerator is not overwhelmed, as congestion can limit airflow and result in temperature level incongruities. Changing the shelving to enable correct air circulation can often solve this issue. Furthermore, inspecting the door seals for any indicators of wear or damages and changing them if essential can aid preserve the integrity of the seal and avoid air leakages. If the refrigeration device is not cooling down correctly, inspecting and changing the thermostat settings might provide a quick service before more thorough troubleshooting is called for. By applying these quick fixes, specialists can deal with typical refrigeration issues efficiently and keep commercial refrigeration systems running smoothly.

Preventative Upkeep Tips

Executing a proactive upkeep timetable is critical for making sure the durability and optimum performance of industrial refrigeration systems. Routine upkeep not just aids avoid pricey malfunctions but also guarantees that the tools operates efficiently, conserving power and decreasing overall operating expense. Right here are some preventative maintenance pointers to keep business refrigeration systems running smoothly:

Inspect and Change Filters: Filthy filters can restrict airflow, making the system work harder and possibly creating damages. Check and change filters regularly to avoid concerns.

Inspect Seals and Gaskets: Leaking seals and gaskets can lead to temperature level fluctuations and energy wastage. Examining and changing damaged seals can aid preserve regular temperatures.

Professional Assistance and Solutions

To keep the optimal performance attained with regular preventative upkeep, looking for specialist support and solutions for industrial refrigeration systems is vital. Expert specialists possess the proficiency and specialized expertise needed to identify and deal with complex problems efficiently. When facing difficult refrigeration troubles, depending on specialist support can save both time and cash in the future.

Expert solutions offer advantages such as access to innovative tools and tools, making certain that fixings are lugged out effectively. Furthermore, professionals are educated to follow sector regulations and security standards, lowering the risk of mishaps and making certain compliance with lawful demands.

Conclusion

To conclude, repairing industrial refrigeration fixing calls for a methodical approach to determining usual problems, using analysis tools and methods, applying fast repairs, and prioritizing preventative maintenance. Expert assistance and services may be essential for more complex troubles - commercial refrigeration repair. By complying with these approaches, businesses can ensure their refrigeration systems run successfully and efficiently, lessening downtime and possible losses

Recognizing the typical issues that afflict industrial refrigeration systems and having a toolkit of analysis strategies at your disposal can make all the difference in quickly determining and treating troubles.Efficient troubleshooting of commercial refrigeration systems relies heavily on making use of specialized analysis devices and methods to determine and settle underlying concerns successfully. By integrating these analysis tools and techniques, go to my site professionals can successfully fix business refrigeration systems and give accurate and fast repair services, lessening downtime and making sure optimum system efficiency.

By applying these quick fixes, technicians can address typical refrigeration troubles effectively and maintain business refrigeration systems running smoothly.

Moreover, professional support can aid extend the lifespan of business refrigeration systems by determining potential issues prior to they intensify.

Report this page